Horizontal Directional Drilling (HDD) is a method used for installing underground pipes, conduits, and cables without disrupting the surface above. This technique has gained popularity in recent years due to its numerous benefits in comparison to traditional trenching methods.

HDD utilizes a drilling machine that is capable of maneuvering beneath the surface to create a horizontal bore path for the installation of utilities. This method is environmentally friendly as it minimizes surface disturbance, reducing the impact on the surrounding area. Additionally, HDD allows for installations in areas where traditional open-cut methods are not feasible, such as under roads, rivers, and existing infrastructure.

Another advantage of HDD is its cost-effectiveness. While the initial setup costs may be higher than traditional methods, the reduced restoration and rehabilitation costs make HDD a more economical option in the long run. Moreover, HDD can be completed in a shorter amount of time, minimizing disruptions to traffic flow and nearby communities.

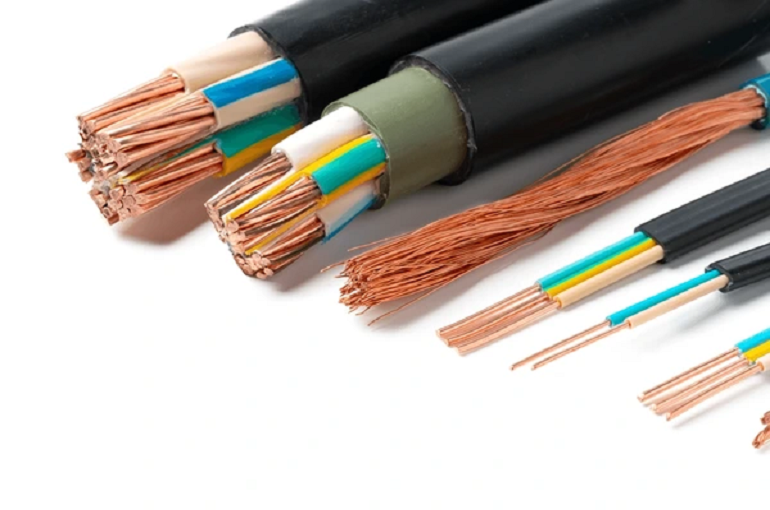

HDD has been used in a variety of industries, including telecommunications, oil and gas, water and sewer, and power distribution. Its versatility and efficiency have made it a preferred method for underground installations globally.

In conclusion, Horizontal Directional Drilling is a valuable technology that offers numerous advantages over traditional trenching methods. Its ability to minimize surface disruptions, reduce costs, and increase efficiency make it a popular choice for various industries. As the demand for underground installations continues to grow, HDD is likely to play a crucial role in meeting these needs.

.png)